Closure Slitting

Closure slitting produces tamper evident breakaway rings on plastic closures. The cutting process makes a series of cuts and bridges in the cap wall.

These slits can be done in the mold. However, mold costs and maintenance are drastically reduced when slitting is done as a secondary operation . There is also a danger that the weakened cap will be damaged upon ejection from the mold.

Nestech machines slit the caps and provide a fold-in feature for any hooks or retaining rings. The caps are completely processed and ready for lining.

Nestech uses straight knife and traditional curved knife slitting processes to produce a breakaway tamper-evident ring on closures. Our knives do NOT need to be heated.

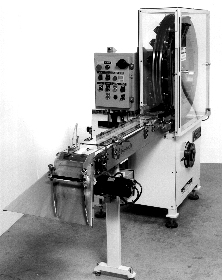

For slower applications, a rotary indexing type machine is used. Speeds range from 200-600/minute. The cutting knives are set with a micrometer backstop for precision depth of cut. These machines produce tamper evident breakaway bands on closures.

High

speeds require a rotary machine with multiple spindles. Speeds are up to

1200/minute.

This machine is equipped with

fast acting caliper brakes and spring

loaded clutches.

Typically, our customers require several caps to be run on the same machine. Our patented tooling makes dedicated machines obsolete. Tooling changes take around 45 minutes.